France Etuves

J911

Séchage de substrats polymère à 210°C

Technical Data

- Field of Activity

- Chamber Volume 2.7 m3

- Max temperature 250 °C

Two ovens designed to dry polymer substrates at 210°C.

- Technical data:

- Working volume: 2700 L

- Internal dimensions WxDxH : 850x1800x1500 mm

- Total installed capacity: 25 kVA

- Maxi temperature: 250°C

- Temperature homogeneity required by the customer: < +/

- 2°C at 60°C, < +/

- 3°C at 210°C

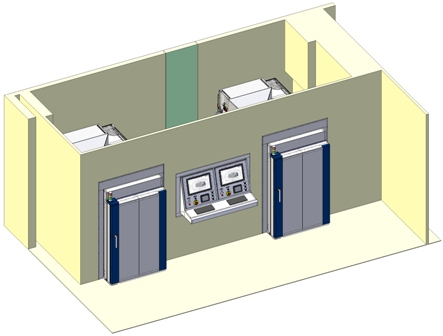

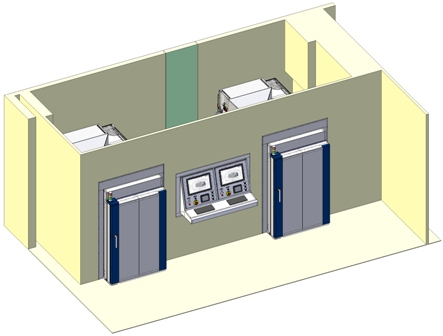

Ovens for clean room

The ovens were designed to be integrated in ISO6 clean room: inner casings welded to be leak-free, tightness of passages???. The front part of the ovens is in the clean room, the back part in the unclassified area.

The inner casings are made of 430 stainless steel.

Each oven has a stack light to indicate a program in progress, a completed program or a default.

The floor of the ovens is composed of a 3 mm ??? thick sheet. Insulated plates are placed under the ovens in order to avoid thermal transfers at floor-level. An access ramp allows to make easier the loading of the trolleys.

Each oven is equipped with a simple vacuum port, an ?? 60 mm access port with cork and with 8 plugs for J thermocouples that allow you to measure and save temperatures at different places in the working volume.

Customized ventilation and cooling systems

Ventilation is horizontal. A diffuser allows you to adjust the orientation of the heated / cooled air blowing into the working volume.

The lower part of the working may be blocked to work only on the top part where the objects are placed.

A pressure switch checks that ventilation works correctly. In case of problem, the functioning of the oven is inhibited until the problem is resolved.

Upstream the air inlet, there is a filtration box composed of a F7 pre-filter and of a E10 filter in order to avoid impurities access inside the oven. A pressure switch measures air flow to check that the filters are not dirty.

At the end of the cycle, a cooling is required. The air outlet is equipped with an air cooling extractor and with a cooling box. The temperature controller controls the extractor. The extracted air is cooled down thanks to the cooling box before being released into the unclassified area.

The cooling box is composed of a battery supplied by a cold water circuit of the customer. The temperature is measured at the output of the battery in order to detect a possible problem on the cooling system.

Temperature control is possible thanks to the Human-Machine Interface, controlled by the FE3000 supervision system of FRANCE ETUVES in case of program launched.

Control panels of the both ovens are integrated into the same electrical box.

Independent safeties protect the oven and the products.