France Etuves

J455

Technical Data

- Field of Activity Recherche

- Chamber Volume 25 litres

- Max temperature 0 °C

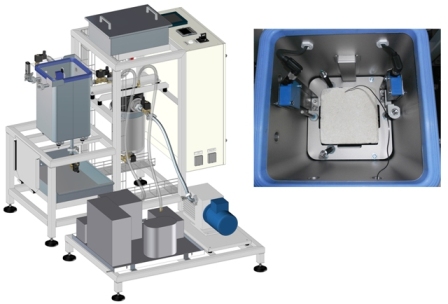

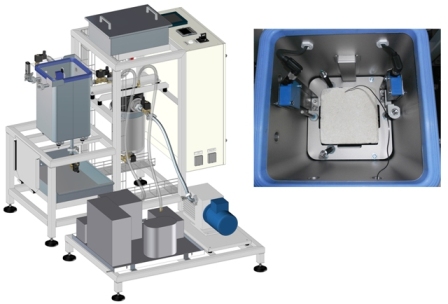

Test bench designed for drying by making vacuum (with diverse vacuum levels) a boulder (150x150x100 mm) soaked with maximum 5% of water.

- Technical data:

- Volume of the casing: 25L

- Dimensions of the casing WxDxH : 250x250x400 mm

- No heating

- Total installed capacity: 2500 VA

- Electrical supply: 230V 1P+N+PE 16A

The test bench is composed of:

1 stainless steel casing, closing by tempered glass,

1 manual filling water tank (with drain valve),

1 drain tray for water of the casing (with drain valve),

1 electrical cabinet with the control devices,

1 two stage oil sealed rotary vane pump,

1 steam separator filter to contain the water steam pumped from the casing in order to protect the pump against humidity detrimental to their efficient operation,

1 chilled water unit to supply the filter with chilled water in order to condensate the water steam.

The whole equipment is fixed on a structure made of mechanically welded tube. Only the chilled water unit and the vacuum pump are on a plate located next to the test bench (in order to limit the vibrations).

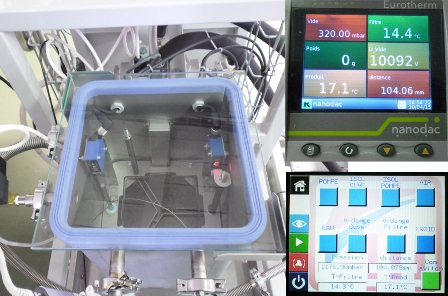

The casing is equipped with a pressure gauge, a temperature probe, a weighing system for the boulder and a water level measurement system.

The systems of weighing and of water level measurement are composed of:

1 laser sensor measuring the distance with a part to enable the weight calculation of the boulder,

1 laser sensor measuring the distance with a float the water level calculation,

1 support on springs for the boulder.

The electrical cabinet is equipped with a control panel that includes, amongst other things, a power on main switch, a Human-Machine Interface allowing you to control the test bench and a recorder saving the values measured by temperature probes inside the casing and in the steam separator filter, by the pressure gauge and the distances measured by the two laser sensors.

Many solenoid valves are controlled by the Human-Machine Interface to enable the several actions.