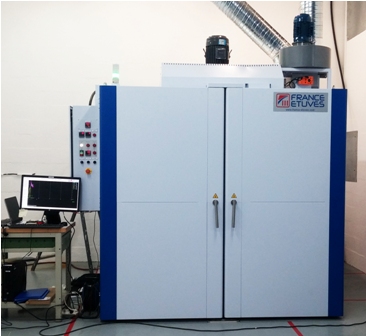

France Etuves

J451

Technical Data

- Field of Activity Aérospatial

- Chamber Volume 8 m3

- Max temperature 200 °C

An 8 m3 oven for the polymerization of composite parts for the space industry.

- Technical data:

- Internal dimensions WxDXH: 2000x2000x2000 mm

- Heating power: 36 kW

- Total installed capacity: 43 kVA

- Mini / maxi temperature: ambient temperature + 20°C / 200°C

- Operating temperature: 155°C +/

- 5°C

- Demanded temperature increase ramp up to 155°C: 2°C/min maxi

- Demanded temperature decrease ramp up to around 50/60°C: 1°C/min maxi

This XXL08 customized oven has many options and accessories which make it unique:

All silicone elements had been replaced by Viton ones or by glass fiber braid.

An insulation plate is placed under the bottom of the oven in order to avoid thermal dissipations at this point. The bottom had been modified: at the entrance of the oven, it is equipped with an access ramp that makes easier the loading access.

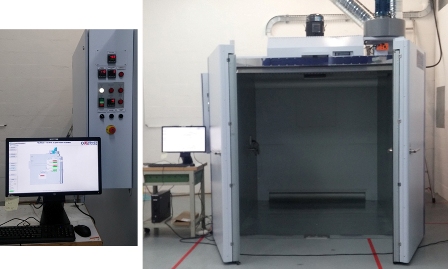

Inside the oven, a box including 4 plugs for TCJ mobile probes had been installed. This allows to measure temperature at different places inside the oven. The temperatures measured by these probes are recorded and exploitable.

Inside the oven, there are two simple female vacuum ports. So you can connect up to two vacuum bags in order to treat under vacuum the products. The vacuum level is measured in the vacuum ramp and is displayed on an electronic device on the control panel. A shut-off valve allows you to quickly and easily stop the vacuum making of the vacuum bags.

The oven is equipped with an extractor for the air change and the air cooling. The percentage of the air change rate must be set in an electronic device. The air cooling system starts automatically when a cooling request is detected by the controller (unexpected overshoot, temperature decrease ramp???.).

The door is equipped with an electromagnetic lock that blocks it above a temperature set in factory according to the customer???s requirement.

The oven is delivered with the FE3000 supervision software developed by France Etuves. The software had been directly installed on a PC of the customer. This software enables an easy, optimized, secured and complete control of the oven.

A stack light with 3 indicators and a buzzer is located on the top front part of the oven. It indicates that a program is in progress or finished and the presence of a default.

A test button allows you to check the good operation of all lighting devices.

Creation of a specific technical documentation for the customer in accordance with his documentary requirements.