France Etuves

J386

Technical Data

- Field of Activity Industrie

- Chamber Volume 1200 litres

- Max temperature 200 °C

Oven for degassing sheets and tools, placed between an ISO6 clean room and an ISO8 clean room.

- Technical data:

- Working volume: 1200 L

- Internal dimensions WxDxH: 1000x1000x1200 mm

- Total installed capacity: 13 kVA

- Mini / maxi temperature: ambient + 20°C / 200°C

Oven for ISO6 and ISO8 clean rooms

The oven is placed between an ISO6 clean room and an ISO8 clean room.

It has two opposite doors: one in ISO8 area for loading, the other in ISO6 area for unloading. Each door has an electromagnetic lock.

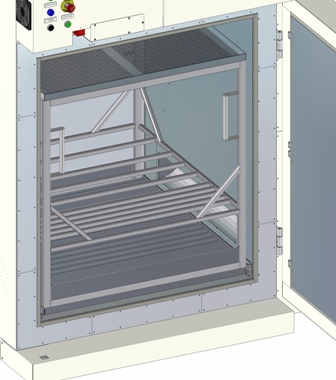

The oven is equipped with a special loading rack mounted on slides. It was designed to support up to 80 kg. The rack goes out in the same way to ISO6 and ISO8 areas.

The top part of the rack is a perforated sheet allowing you to put small parts. The bottom part is composed of dividers allowing you to load sheets. Under the dividers there is a perforated sheet to let free air circulation.

The inner casing is made of welded airtight 304 stainless steel. The outer casing is also made airtight in order to respect the clean room compatibility.

In the ISO8 area, there is an electrical cabinet that includes an Human-Machine Interface (for displaying the program as curves, setting and launching programs, defaults management and accessing to the configuration), a safety controller, a power on indicator, a default indicator and an on/off switch.

The electrical cabinet is ventilated. A probe checks that temperature inside the cabinet is not higher than 50°C. If temperature is exceeding 50°C, an air change cools down temperature. When hot air goes out of the electrical cabinet, fresh air from ISO area enters into it.

On both sides, the oven is equipped with a control panel including an emergency stop, a push-button to launch program, a push-button to request door???s opening, a program in progress indicator and a locked door indicator.

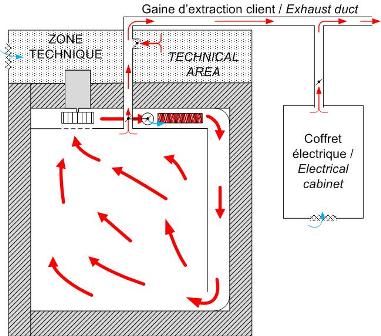

At each door???s opening request, the HMI checks that the opposite door is closed and closes the air inlet and outlet of the oven, in order to not mix air from ISO6 and ISO8 areas.

In the ISO8 area, the oven is equipped with an independent mechanical safety thermostat with reset to protect the oven against overheating.

The top part of the oven (technical area) is formed and is equipped with airtight access hatches on both sides. There is also a covering up to the ceiling of the premises.

The technical area is ventilated for heat discharge: the fresh air comes from ISO8 area.

The air change / cooling inlet and outlet of the oven are equipped with motorized flaps. Air change rate is adjustable in the HMI. Fresh air is sucked from ISO6 area and enters directly in the ventilation tunnel of the oven. Hot air going out of the oven, technical area and electrical cabinet is guided towards the exhaust system of the customer.