France Etuves

J352

Polymérisation de pièces en composite.

Technical Data

- Field of Activity Aéronautique

- Chamber Volume 51 m3

- Max temperature 200 °C

A 51m3 oven for the polymerization of composite parts in a closed aluminum mould.

- Technical data:

- Internal dimensions W x D x H: 4,5 x 4,5 x 2,5 m

- Maxi temperature: 200°C

- Demanded temperature increase ramp: between 0,3°C/min and 3°C/min

- Total installed capacity: 137 kVA

A modular oven with customized dimensions

The oven is composed of a front door part, of two around 25m3 modules and of a back part.

Each module has a fan engine, heating elements that product 55 kW of heating power, an air change system, an air cooling system, two inner lights and two ?? 20 mm access ports with corks.

The oven is with double-flux ventilation. The fan engines are located at the center; the reheated air is blown from the ceiling on the both lateral sides.

The air change systems are composed of an air inlet and outlet with motorized flaps. The air change flow is adjustable.

The air cooling systems are composed of an air cooling extractor and of air inlet and outlet with motorized flaps. The air cooling systems are managed by the controller. When an air cooling is required (e.g.: during a temperature decrease ramp), the air cooling inlets and outlets open and the extractors work.

An insulation plate is placed under the floor of the oven in order to avoid thermal dissipations.

Inside the oven, there are 8 plugs for TCJ mobile probes. The mobile probes enable to measure temperature at different places in the working volume. Temperatures measured by these mobile probes are displayed and recorded.

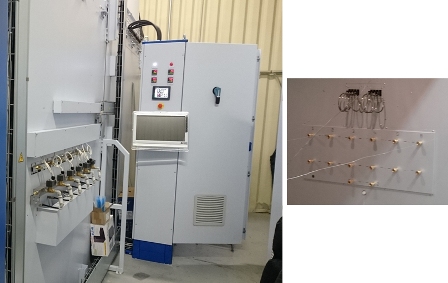

The oven is equipped with systems that enable to make vacuum in vacuum bags and put them under pressure. These systems are composed of a vacuum ramp (6 connectors), of a measurement ramp (6 connectors, measure by piezo sensors) and of a pressure ramp (2 connectors). The vacuum connectors are independent.

An optimized management of the oven

The oven may be controlled from a Human-Machine Interface or from the FE3000 supervision software developed by FRANCE ETUVES.

The FE3000 supervision software allows you, among other things, to create temperature and vacuum programs. The air change flow, the set point temperature, the set point vacuum / pressure level can be set for each step of the program. The temperatures measured by the mobile probes are displayed and recorded.

The Human-Machine Interface allows you to make temperature and vacuum / pressure simple control, to set the air change flow, to control vacuum, to see temperatures measured by the mobile probes and vacuum levels measured by the piezo sensors, to set control parameters???

A 3-colors stack light with buzzer indicate a program in progress or finished and the presence of a default.

An emergency stop allows you to turn off the oven in case of problem.

If you open the door, ventilation, heating and extraction are cut off and the inner lightings turn on.

Each module is equipped with an independent safety thermostat with reset (class 2 protection). They measure temperature near the heating elements and cut off heating in case of overheating.

At the customer???s request, a conformity control according to the AMS2750-E, type D standard was performed by a FRANCE ETUVES technician specialized in metrology. The report includes a homogeneity control and the calibration certificates of the measurement chains and of mobile probes.