France Etuves

J238

Technical Data

- Field of Activity Aéronautique

- Chamber Volume 384 litres

- Max temperature 200 °C

Special oven designed to be adapted on different traction benches.

- Technical data:

- Working volume: 384 L

- Internal dimensions WxDxH: 800x600x800 mm

- Heating power: oven = 4000 W / window = 880 W

- Total installed capacity: 5300 VA

- Maxi temperature: 200°C

- Mini temperature: ambient temperature + 10°C / with LN2 injection: -55°C

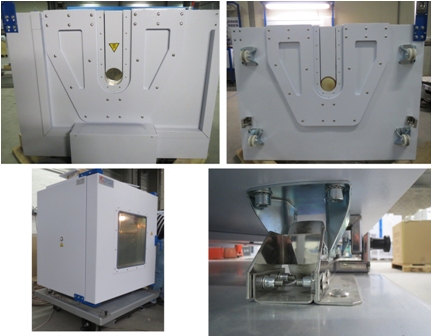

Oven for traction benches, delivered with its lift table

The oven was designed to be integrated on different traction benches.

The oven is equipped with passages with removable corks on the top and on the bottom of the inner casing so that the shafts of the traction bench pass.

The oven is delivered with a lift table on which it can be fixed. The lift table and the traction benches are equipped with guide rails. The oven is on castors that allow you to move it securely from the table to the bench and vice-versa. The guide rails are equipped with stops and fastenings for the oven.

Characteristics of the oven

The inner sheets of the oven are made of stainless steel 304.

The oven has an inner lighting controlled by a switch on the electrical cabinet, a ?? 80 mm access port with cork on the right lateral side and a ?? 20 mm access port with cork on the left lateral side. The access ports enable to pass probes for the various controls made by the customer.

The electrical cabinet is remote. The oven is equipped with a 3m cable to connect to the cabinet. The electrical cabinet is protected against impacts that may damage it during the process.

The fan engine is equipped with a variable speed drive that allows to vary airflow from the minimum flow of good functioning to 100%.

In the working volume, there are three mobile thermocouple K probes. They enable to measure temperature at different locations in the working volume. Connect a measuring and recording instrument to the connectors located at the backside of the oven in order to record temperatures measured by these mobile probes.

At each door???s opening when the oven works, heating, ventilation and nitrogen injection are turned off. This allows to protect the operator and components of the oven.

Heating & cooling

Heating is ensured by two heating elements ideally placed in the air flow.

The oven is equipped with a system which injects liquid nitrogen (LN2) in order to reach -55°C.

The oven is equipped with a cryogenic box that includes a G 1/4 connector for LN2 supply (pressure 0,5 bars) and a cryogenic solenoid valve that allows the nitrogen injection. Nitrogen is injected in front of the aspiration grid.

The insulated door is equipped with a multi glazing window with heating elements to avoid condensation during cooling down phase.

The nitrogen injection is controlled by a switch. When the switch is turned on and that there is a cooling request (decrease of the set point temperature) and a +4°C deviation in comparison with the set point, the cryogenic solenoid valve opens and the heating elements of the window are activated.

The oven is equipped with control systems: it checks that the measured temperature does not fall to -60°C and that it does not exceed the set point temperature.