France Etuves

H954

Technical Data

- Field of Activity Aéronautique

- Chamber Volume 2.25 m3

- Max temperature 250 °C

Oven for tempering of aluminum nuts.

Oven complied with the APAVE certification

Oven in compliance with AMS2750E standard, D-type instrumentation, class 2 (+/ 6°C)

Arrangement of the load in the oven in compliance with AMS2770J

Maxi temperature: 250°C

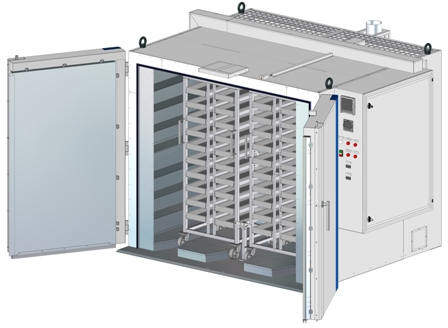

Internal dimensions WxDxH: 1500x1000x1500 mm

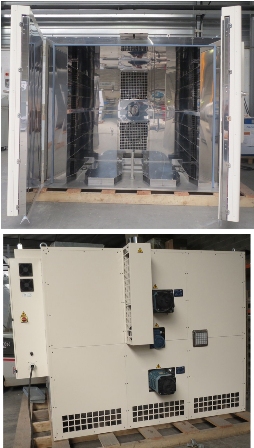

The inner sheets of this special oven are made of stainless steel 430.

The external sheets are made of steel with epoxy paints in the colors of the customer company.

The oven can contain two trolleys especially designed for the process. The bottom of the oven is insulated with passages for trolleys castors. An insulating plate is placed under the oven in order to avoid thermal dissipations to the castors passages.

An ?? 20 mm access port with cork is available to pass control thermocouple probes.

The oven is equipped with two fan engines, one in the top part and another in the bottom part. The ventilation flow is horizontal.

A cooling system composed of an air cooling extractor and of an inlet and an outlet with motorized flaps, is controlled by the controller: if the measured temperature exceeds the set point temperature with at least 2°C, the air inlet and outlet open entirely and the extractor works. The air inlet is equipped with a G4 filter in order to avoid that impurities enter in the oven.

When the oven works, heating, ventilation and cooling are cut off at each door???s opening.

Temperature control is ensured by a dual-loop profiler. It allows control on two areas: the top part and the bottom one. It measures temperature thanks to two K thermocouple probes delivered with their calibration certificates.

Two safety controllers ensure the product safety: one for the top part, one for the bottom part. They measure temperature in each area thanks to two K thermocouple probes delivered with their calibration certificates.

A digital recorder saves the set point temperatures and the temperatures measured by the control probes. A RJ45 connector allows you to retrieve the recorded data.

Two mechanical independent safety thermostats with manual reset (protection class 2) ensure the protection of the oven against possible overheating.

An emergency stop allows you to turn off the oven in case of problem.

The electrical cabinet is equipped with a stack light and buzzer that indicates when a ventilation problem occurs, when a program is in progress and when no program is launched.

In the electrical cabinet, a 220V socket is available to connect calibration devices.

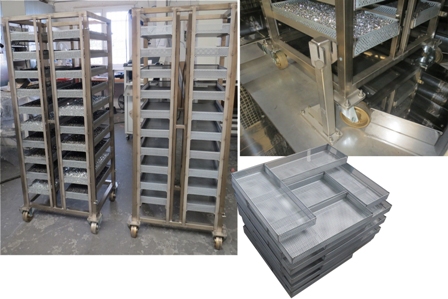

The oven is delivered with two trolleys especially designed for the process. The trolleys are made of stainless steel and are on castors. Each trolley can contain 20 R4T6-perforated stainless steel trays. The bottom of the oven is equipped with stops in order to guide the trolleys during loading. A locking system enables to maintain trolleys in position.