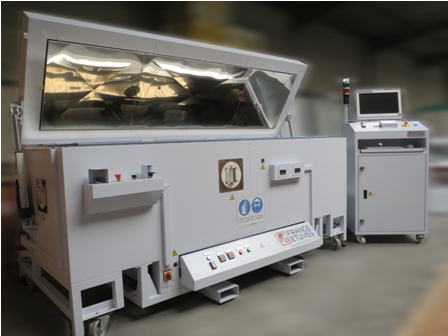

France Etuves

H138

Technical Data

- Field of Activity Recherche

- Chamber Volume 900 litres

- Max temperature 280 °C

Special top loading oven for testing tools at 270°C with possible release of sulfur dioxide (SO2) in case of rupture.

- Technical data:

- Internal dimensions WxDxH: 2500x600x600 mm

- Mini / maxi temperature: 50°C / 280°C

- Total installed capacity: 27,5 kVA

- Airborne noise, without extraction: less than 60 dB

An atypical top loading oven

The door opens upwards; two electric jacks assist the door???s opening and closing. A control console, placed on the oven, has a bimanual button that controls the jacks. An inductive detector ensures that the door is correctly closed.

The inner sheets of the oven are made of stainless steel. Four movable supports allow you to load one or two different tools. Adjustable anti-rotation devices guarantee the tools??? immobility during the processes.

The oven is on a sub-frame with swivel casters to move the oven for short journeys and with high-adjustable feet to make the oven on level once it has been installed.

At the lower part, the oven is equipped with a handling frame for forklift truck. It allows you to move the oven easily for long journeys and is removable.

The oven has an ?? 170 mm access port with cork on each lateral side. They allow to pass cables.

The oven is equipped with a door control console, an electrical cabinet with control panel and a remote control console. The remote control console includes the FE3000 supervision software; this allows to control the oven completely and at a distance away in order to not be in the same room when the oven works to protect oneself against possible sulfur dioxide release.

The oven has 8 connectors for mobile TCJ probes. These probes allow to measure temperature anywhere in the working volume. The measured data are recorded by the FE3000 supervision software.

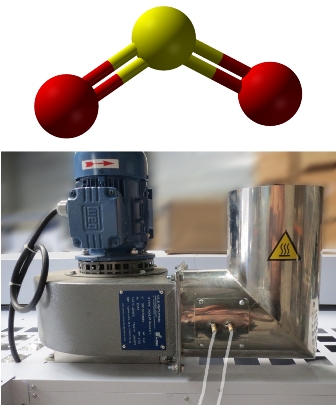

Safety system against sulfur dioxide release

Heating tools may cause a sulfur dioxide release in case of rupture. A SO2 detection system is installed.

In addition to ensure oven???s cooling, an extractor evacuates the sulfur dioxide that could be detected.

Air in the working volume is constantly monitored: it is pumped from the working volume then it is analyzed by many components located in a box reserved for SO2 detection. In case of SO2 detection and from a trigger point (set in a automaton), a default appears, heating is cut off, the air inlet and outlet open and the extractor works in order to remove contaminated air.

A pressure switch located after the extractor in the extraction duct verifies that the extractor works correctly when extraction is necessary.

On the front side of the oven, a vent access port protects the oven against overpressure.

A test button for SO2 presence simulation allows you to check that the safety system works well.

An oven completely under control

In addition to a protective system against sulfur dioxide, the oven has many other safety devices.

A safety controller measures temperature inside the oven to protect the products against possible overheating. A mechanical safety thermostat protects the oven against possible overheating.

A safety device checks that inner air ventilation works well.

A visual and sound alarm informs the operators that a default is detected.

The oven is equipped with an automaton with a GSM module. It may be configured so that a SMS is sent to people in case of default detection.