France Etuves

G221

Technical Data

- Field of Activity Aéronautique

- Chamber Volume 70 m3

- Max temperature 200 °C

Oven for the polymerization of composite parts for an important Asian aeronautics manufacturer.

- Technical Data:

- Volume: 70 m3

- Maximum Temperature: 200°C

- Inner Casing Size: 3400 x 10400 x 2000 mm

- Wattage: 312 kwatts

An atypical construction

The oven is more than 10m deep and more than 5m tall.

The floor of the oven is in the ground of the room; it is at ground level to make loading by trolleys effortless.

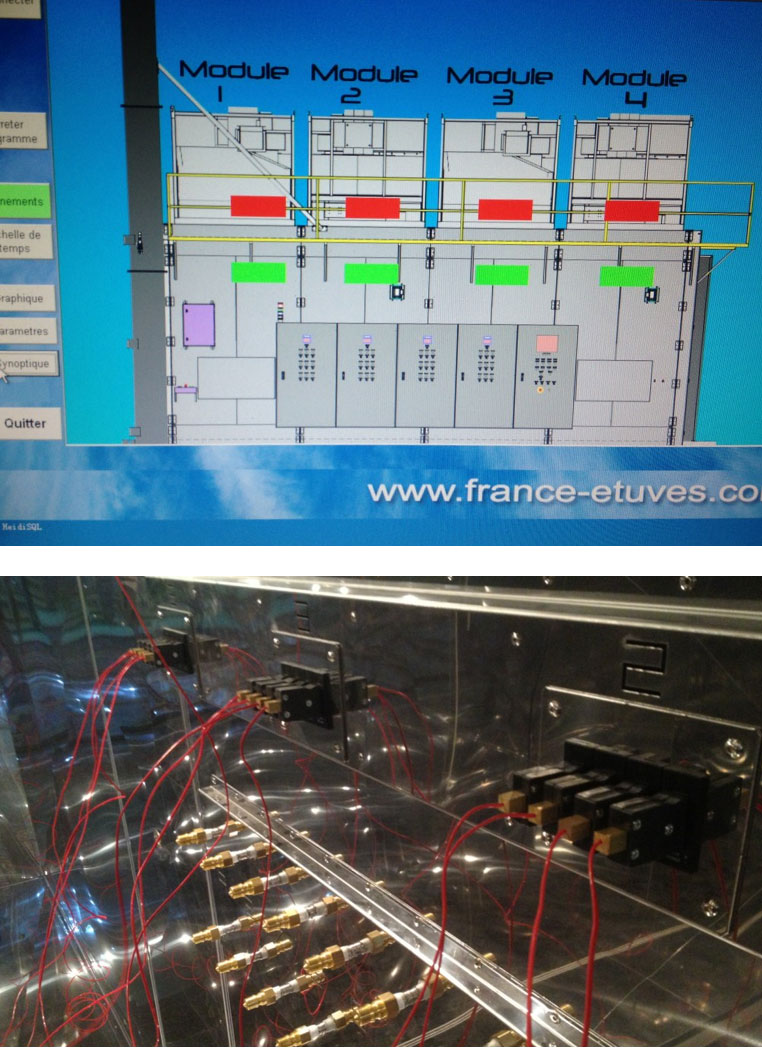

The oven was split into 4 modules to make the transport by container easier. Each module has ventilation, heating and cooling units.

The inner walls are made of corrosion resistant stainless steel.

The door opens via a vertical lift door powered by a gear motor at the front side of the oven. Sensors ensure the correct positioning of the door.

The main electrical cabinet of the oven is remote and dismountable in two parts. Only the door control console is fixed and placed at the entrance of the oven.

A safety cable running along the inside of the oven allows you to completely stop the oven in case an operator inadvertently gets stuck inside. An emergency exit, on the rear side of the oven, allows the stuck operator to escape.

Twelve interior lights are distributed throughout the oven. The entire area is lit.

Each cooling system has a cooling outlet and inlet with a motorized flap. A switch allows you to choose the cooling control according to the controller or operate it manually.

The maintenance staff can easily access the top part of the oven: a ladder and a gangway allow access by the right side of the oven.

For maintenance inside the oven, the door must be completely open. Manual door lock systems protect the maintenance staff against the doors unexpected fall.

Controlling your oven has never been easier

The oven is equipped with the FE3000 supervision software, allowing the management of all characteristics of the oven. Nevertheless, additional elements are available to ensure the functioning of the oven in case of a malfunction in the supervision software.

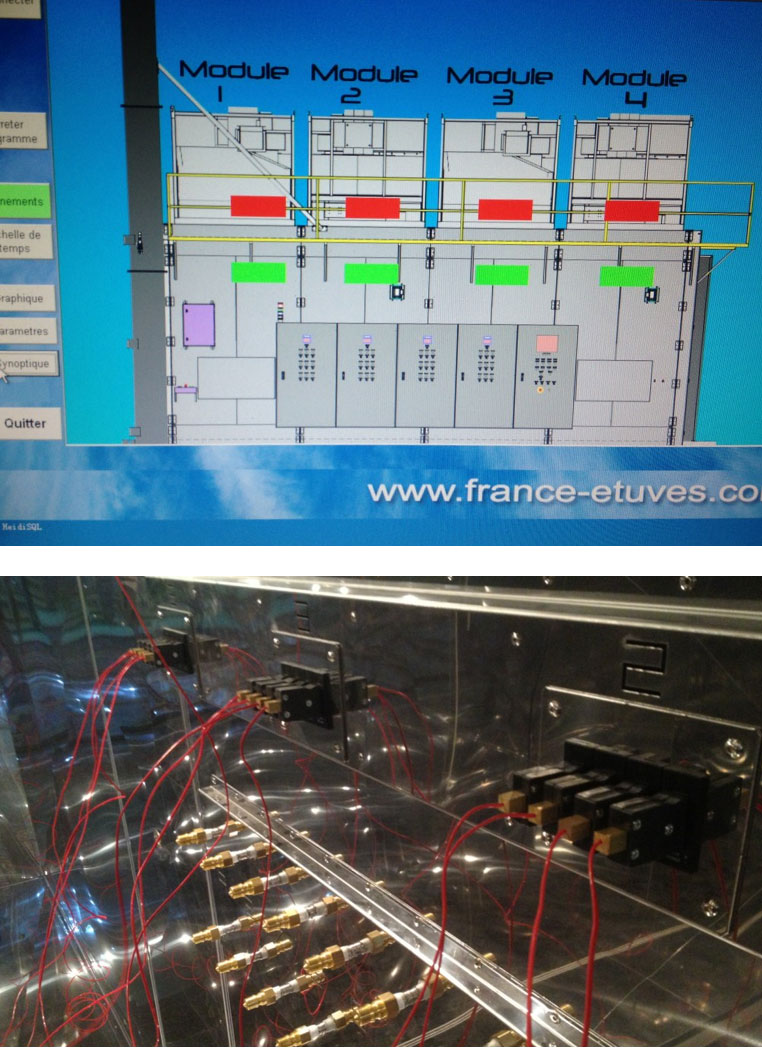

Two modules are each equipped with 9 vacuum ports. These 18 vacuum ports are coupled with 18 vacuum control ports.

A management system PLC allows the vacuum system, the state of the door and the alarms to be controlled.

Two modules are equipped with thermocouple plugs. Then the operator can monitor the temperature wherever they are in the oven.

A stack light allows the operator, even when far from the oven, to monitor the state of the oven.

The electrical cabinet is equipped with two recorders. Each recorder saves the parameters of two modules: temperatures measured by the thermocouples, measurements of the vacuum level, and temperatures of the hottest and coolest points of the 2 modules.

Emergency stop buttons allow you to stop the oven in the event of an anomaly.