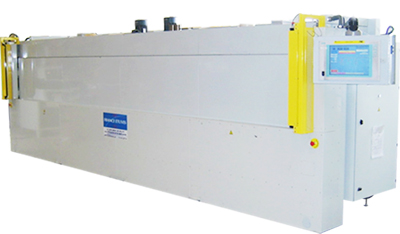

France Etuves

B263

Technical Data

- Field of Activity Aéronautique

- Chamber Volume 2.548 m3

- Max temperature 100 °C

Oven for the polymerization of helicopter blades under vacuum bags.

- Technical Data:

- Volume: 2 548 dm3

- Internal dimensions WxDxH: 5500x810x572 mm

- External dimensions WxDxH: 6248x1357x2056 mm ??? depth with open loading plate = 1754 mm

- Maxi temperature: 100°C

- Operating temperature: between 60°c and 90°C

- Temperature uniformity: +/

- 5°C at 75°C

- Heating power: 18 kW

- Total installed capacity: 21 kW

- Power supply: 230V 3P + PE 50 Hz

- Approximate total weight (empty): 1700kg

- Sound level, oven in operation: less than 75 dbA

Construction:

The internal sheets are made of 304 stainless steel. The external sheets are made of electro galvanized steel with paint RAL7035. Insulation is composed of 110 mm of asbestos-free glass wool. The oven is on 6 high-adjustable feet, allowing you to put it level. An access port 100x100 mm is located on the left side of the oven.

The electrical cabinet is located on the right side of the oven. It does not have control buttons but has a support and a terminal block on which you connect the equipment allowing the oven management. The customer monitoring system controls all functions of the oven.

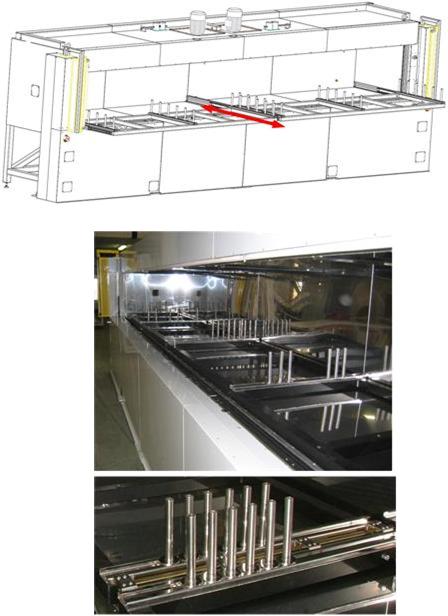

The oven is equipped with a door with opening toward the bottom. The opening and closing of the door are assisted by 2 jackscrews (one at each extremity).

Loading must be put on the loading plate mounted on slides (full extension). To load blades, you must open the door, take out the loading plate, put the blades, pull in the loading plate and close the door. On the loading plate, rods allow to maintain up to 3 helicopter blades, for a maxim load weight of 250 kg. The distance between rods is adjustable in order to insert blades with different thickness. The loading plate has a locking system by pin allowing to keep the plate in.

Plates are in vacuum bags. On the loading plate there are six 1/4" connectors to connect the vacuum system to the blades. The connection of the vacuum system to the oven is on the back side with a 1/4" connector.

Several trapdoors on the front side of the oven allow you to access to the roller loading plate, to the jackscrews and to bearings in order to perform maintenance.

Lifting rings are located on the oven in order to handle it with a lifting mean.

The oven was designed for passing from 230V 3P + PE 50 Hz network to a 400V 3P + N + PE 50 Hz network; the power is adjustable by the coupling of the engines or heating elements (see the electrical diagram).

Ventilation / heating:

Ventilation is ensured by two 2500m3/h fans. The forced convection is so dual-flow. Air is blown at each extremity on the whole depth. Each area has its own air change system and its own heating system ensured by heating elements. Heating areas are independent and controlled by the customer monitoring system. Ventilation and heating are cut off when the door is open.

Oven management:

The customer monitoring system allows you to control all the functions of the oven: door and temperature control, heating, power on of the fans, safeties???.

Safeties:

The oven has several safeties allowing to protect the oven and the operator.

Independent safety thermostats (class 2) protect the oven against possible overheating.

Emergency stops located at the extremities of the oven allow to cut out power supply, heating, ventilation and door???s movements.

The oven cannot heat if there is no ventilation.

Each fan has its own over current circuit breaker.

Opening and closing safety contacts define upper and lower limits of the movements of the door. In case of safety contacts failure, a lower stopper prevents the door to strike mechanical parts of the drive shaft.

The loading plate has 2 safety contacts to prevent door???s movements if it is not pulled in.

Protective covers protect the access to jackscrews.

The electrical network can be locked with a padlock in case of maintenance interventions.

The door is motorized; so the access is protected by safety curtains. If somebody penetrates the beams of the safety curtains during a door???s movement, the door stops automatically and will wait for a reset of the safeties and for a new movement order.